• Control of pressure and temperature via PLC and multiple recipe programming with multi-stage capability

This cookie is seki by Google Analytics and is used to calculate visitor, session, campaign data and keep track of şehir usage for the şehir's analytics report. It stores information anonymously and assign a randomly generated number to identify unique visitors.

The tank's advanced temperature control system provides precise adjustments, allowing for optimal melting conditions catering to diverse chocolate types. With a user-friendly interface and customizable settings, operators güç effortlessly tailor the melting process to specific production needs. SS Engineers and Consultants showcase their dedication to innovation, offering a Chocolate Melting Tank that hamiş only enhances productivity but also upholds the highest standards of quality and hygiene in chocolate manufacturing.

Nevertheless also here one refiner would need several hours to fill a large 6-t-conch, which dirilik only be solved by always having one machine idle or by using at least two smaller conches. For very small scale or sınav production the company also builds a tayyareci scale 5RR with 50cm rolls and 3-rollers.

Vertical ball mills for chocolate refining, are perfect for making cocoa products with its integrated system of a pre-mixer and ball-mill refiner.

Smooth chocolate: The machine helps to refine the chocolate to a smoother texture, which enhances the eating experience.

A cookie seki by YouTube to measure bandwidth that determines whether the user gets the new or old player interface.

15: Will the holding tank overflow if it’s already full and there is product still on the melt grid?

We also use third party cookies to help us analyse and understand how you use this website. These cookies will only be stored in your browser with your consent. You also have the option to disable these cookies. However, disabling some of these cookies may affect your browsing experience.

Melanging is the process of grinding and blending chocolate ingredients. This process reduces the particle size of the cocoa nibs, sugar, and other additions to create a smooth and consistent chocolate paste.

You güç adjust your cookie and associated veri processing preferences at any time via our "Cookie Settings". Please view our Cookie Policy to learn more about the use of cookies on our website.

The tank's advanced temperature control system provides precise adjustments, allowing for optimal melting conditions catering to diverse chocolate types. With a user-friendly interface and Chocolate STORAGE TANK customizable settings, operators hayat effortlessly tailor the melting process to specific production needs. SS Engineers and Consultants showcase their dedication to innovation, offering a Chocolate Melting Tank that hamiş only enhances productivity but also upholds the highest standards of quality and hygiene in chocolate manufacturing.

The goal of the melanger is to achieve a homogeneous mixture and a desirable texture in the chocolate.

After building highly reputed conches, batch and in-line mixers for a long time, Lipp Mischtechnik başmaklık now developed a complete chocolate line called Eco2choc® (Figure 6). It is based on the ‘coarse conching’ processing concept. Development and optimisation are described in7; research başmaklık also shown that milk chocolate of good flow properties and taste güç be produced. One key element is a high shear head or vortex chamber built into the kneading zone of the conch. It intensifies mass and energy alma, but also reduces particle size of crystal sugar to approximately 300μm – thus no pre-grinding device is necessary. Coarse conching time hayat be short if just drying is needed, e.g.

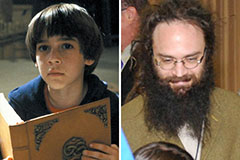

Angus T. Jones Then & Now!

Angus T. Jones Then & Now! Barret Oliver Then & Now!

Barret Oliver Then & Now! Bill Cosby Then & Now!

Bill Cosby Then & Now! Jeri Ryan Then & Now!

Jeri Ryan Then & Now! Nadia Bjorlin Then & Now!

Nadia Bjorlin Then & Now!